CMT焊接技术的应用、发展与展望

赵锴 1 杨成刚 2易翔 3

(1. 江西恒大高新技术股份有限公司,江西 南昌 330096; 2. 南昌航空大学,江西 南昌 330063; 3. 珠海市福尼斯焊接技术有限公司,广东 珠海 519015 )

DOI:10.7512/j.issn.1001-2303.2022.05.09

0 CMT概述

1 CMT的应用

1.1 表面堆焊

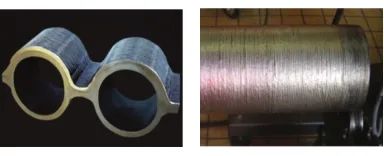

图 1 膜式水冷壁和管子外壁堆焊Inconel 625

Fig.1 Overlaying Inconel 625 on membrane water wall and outer wall of pipe

1.2 超薄板焊接

1.3 大间隙焊缝焊接

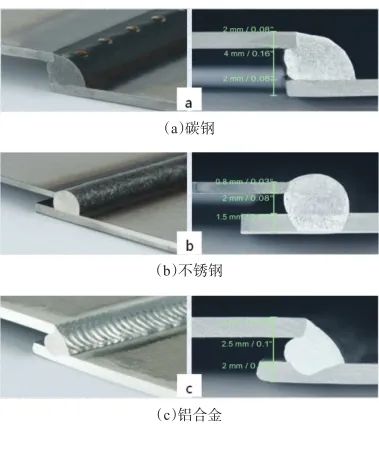

图2 接头宏观形貌

Fig.2 Macro morphology of joint

1.4 Al与镀锌钢异种材料的焊接

1.5 轻合金构件焊接

2 CMT技术进展与展望

2.1 CMT电弧增材制造

图4 CMT增材制造成形件[33]Fig.4 CMT additive manufacturing formed parts[33]

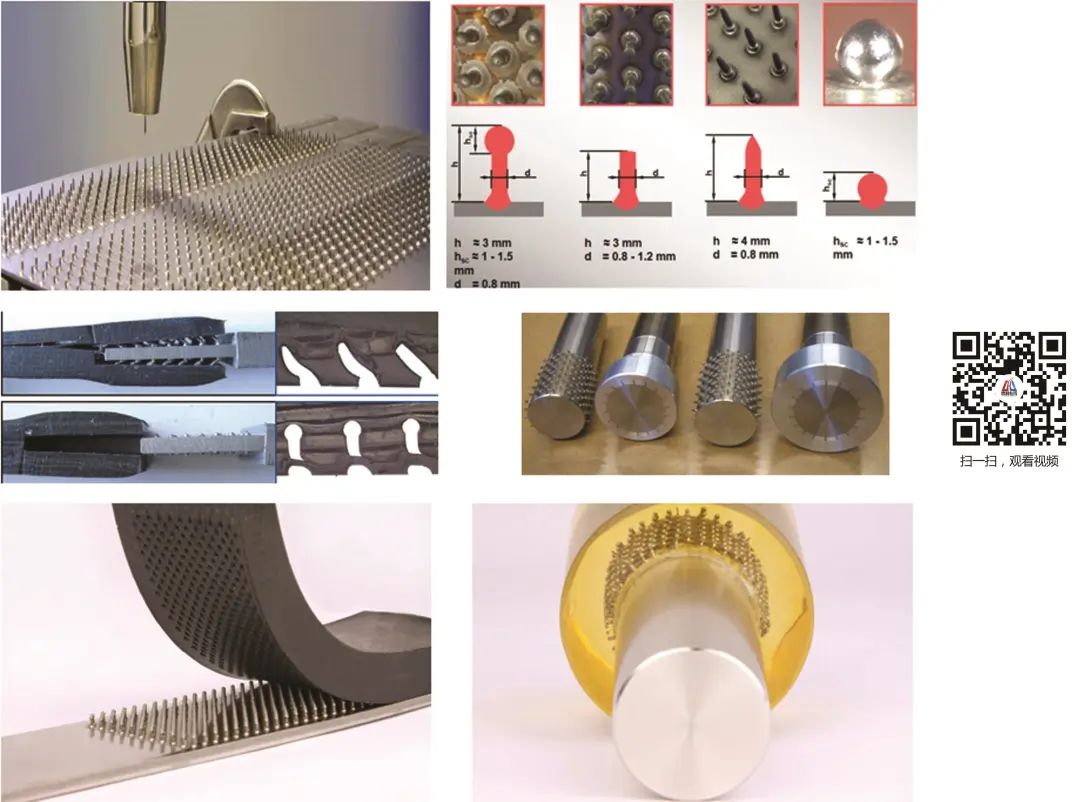

图4 CMT增材制造成形件[33]Fig.4 CMT additive manufacturing formed parts[33]2.2 CMT销钉

2.3 激光-CMT复合焊

3 结论与展望

1. Näkki J. Properties of alloy 625 claddings made with laser and CMT methods[R]. CMT –Nordic business opportunities from coating and additive manufacturing,2018.

2. Lorenzin G, Rutili G. The innovative use of low heat input in welding:experiences on ‘cladding’and brazing using the CMT process[J]. Welding International, 2009, 23(8): 622-632.

3. Adamiec J. High temperature corrosion of power boiler components cladded with nickel alloys[J]. Materials characterization, 2009, 60(10): 1093-1099.

4. Mohammadi Zahrani E, Alfantazi A M. Hot corrosion of Inconel 625 overlay weld cladding in smelting off-gas environment[J]. Metallurgical and Materials Transactions A, 2013, 44(10): 4671-4699.

5. Rozmus-Górnikowska M, Blicharski M, Kusiński J, et al. Influence of boiler pipe cladding techniques on their microstructure and properties[J]. Archives of metallurgy and materials, 2013, 58:4-14.

6. Adamiec J, Kierzek A. Padding of the components of waste combustion boilers with the use of nickel alloys[J]. Inżynieria Materiałowa, 2008, 29(4): 380-385.

7. Goecke S. Energiereduziertes Lichtbogen-Fugeverfahren fur warmeempfindliche Werkstoffe[J]. DVS BERICHTE, 2005,237: 44.

8. 上山智之.通过CBT方法开发低热输入低飞溅CO2/MAG交流焊接系统[J].电焊机,2009,39(09):10-13,87.

Tomoyuki Ueyama. Development of low heat input and spatter reduction CO2/MAG alternating current welding system by controlled bridge transfer process[J]. Electric Welding Machine,2009,39(09):10-13,87.

9. Talalaev R, Veinthal R, Laansoo A, et al. Cold metal transfer (CMT) welding of thin sheet metal products[J]. Estonian Journal of Engineering, 2012, 18(3): 243.

10. Grzybicki M, Jakubowski J. Comparative tests of steel car body sheet welds made using CMT and MIG/MAG methods[J]. Welding international, 2013, 27(8): 610-615.

11. 朱宇虹, 耿志卿. 薄板焊接的极限——CMT 冷金属过渡焊接技术[J]. 电焊机, 2011, 41(4): 69-71.

Zhu Yuhong, Geng Zhiqing. Limitation of sheet metal welding-CMT cool metal transition technique[J]. Electric Welding Machine, 2011, 41(4): 69-71.

12. İrizalp A O, Durmuş H, Yüksel N, et al. Cold metal transfer welding of AA1050 aluminum thin sheets[J]. Matéria (Rio de Janeiro), 2016(21): 615-622.

13. Ahmad R, Bakar M A. Effect of a post-weld heat treatment on the mechanical and microstructure properties of AA6061 joints welded by the gas metal arc welding cold metal transfer method[J]. Materials & Design, 2011, 32(10): 5120-5126.

14. Van de Ven J D, Erdman A G. Bridging gaps in laser transmission welding of thermoplastics[J]. Journal of Manufacturing Science and Engineering, 2007,129: 1011-1018.

15. Ahsan M R U, Kim T, bong Kim D, et al. A study on the effect of wire composition on welding with gap and offset in cold metal transfer (CMT) GMAW[J]. Journal of Welding and Joining, 2018, 36(5): 12-18.

16. Balasubramanian M, Choudary M V, Nagaraja A, et al. Cold metal transfer process–a review[J]. Materials Today:Proceedings, 2020(33): 543-549.

17. Basak S, Das H, Pal T K, et al. Characterization of intermetallics in aluminum to zinc coated interstitial free steel joining by pulsed MIG brazing for automotive application[J]. Materials Characterization, 2016, 112: 229-237.

18. Jácome L A, Weber S, Leitner A, et al. Influence of filler composition on the microstructure and mechanical properties of steel—Aluminum joints produced by metal arc joining[J]. Advanced Engineering Materials, 2009, 11(5): 350-358.

19. Yang S, Zhang J, Lian J, et al. Welding of aluminum alloy to zinc coated steel by cold metal transfer[J]. Materials & Design, 2013(49): 602-612.

20. Singh J, Arora K S, Shukla D K. Dissimilar MIG-CMT weld-brazing of aluminium to steel:A review[J]. Journal of Alloys and Compounds, 2019,783: 753-764.

21. Ola O T, Valdez R L, Oluwasegun K M, et al. Process variable optimization in the cold metal transfer weld repair of aerospace ZE41A-T5 alloy using central composite design[J]. The International Journal of Advanced Manufacturing Technology, 2019, 105(11): 4827-4835.

22. Chang C C, Chou C P, Hsu S N, et al. Effect of laser welding on properties of dissimilar joint of Al-Mg-Si and Al-Mn aluminum alloys[J]. Journal of Materials Science & Technology, 2010, 26(3): 276-282.

23. Xiao R, Zhang X. Problems and issues in laser beam welding of aluminum–lithium alloys[J]. Journal of Manufacturing Processes, 2014, 16(2): 166-175.

24. Gibson B T, Ballun M C, Cook G E, et al. Friction stir lap joining of 2198 aluminum–lithium alloy with weaving and pulsing variants[J]. Journal of Manufacturing Processes, 2015(18): 12-22.

25. Tian Y, Robson J D, Riekehr S, et al. Process optimization of dual-laser beam welding of advanced Al-Li alloys through hot cracking susceptibility modeling[J]. Metallurgical and Materials Transactions A, 2016, 47(7): 3533-3544.

26. Han B, Chen Y, Tao W, et al. Microstructural evolution and interfacial crack corrosion behavior of double-sided laser beam welded 2060/2099 Al-Li alloys T-joints[J]. Materials & Design, 2017,135: 353-365.

27. 汪殿龙,陈彦朝,李海洋,等.高频脉冲电流耦合交流CMT焊对2060铝合金接头组织与力学性能的影响[J].热加工工艺,2017(21):13-16.

WANG D L, CHEN Y C, LI H Y, et al. Effects of AC CMT welding coupled with high-frequency pulse current on microstructure and mechanical properties of 2060 Al-Li alloy joint[J]. Hot Working Technology,2017(21):13-16.

28. Liu H, Yang S, Xie C, et al. Microstructure characterization and mechanism of fatigue crack initiation near pores for 6005A CMT welded joint[J]. Materials Science and Engineering:A, 2017,707: 22-29.

29. Vasvári G F, Csonka D, Zsebe T, et al. CMT Additive Manufacturing Parameters Defining Aluminium Alloy Object Geometry and Mechanical Properties[J]. Materials, 2021, 14(6): 1545.

30. Chen X, Su C, Wang Y, et al. Cold metal transfer (CMT) based wire and arc additive manufacture (WAAM) system[J]. Journal of Surface Investigation:X-ray, Synchrotron and Neutron Techniques, 2018, 12(6): 1278-1284.

31. Paskual A, Álvarez P, Suárez A. Study on arc welding processes for high deposition rate additive manufacturing[J]. Procedia Cirp, 2018, 68: 358-362.

32. G Vasvári,T Zsebe,F Dako,et al. Assessment of welding parameters in CMT additive manufacturing[C]. //EXPRES 2020.

33. Cadiou S, Courtois M, Carin M, et al. 3D heat transfer, fluid flow and electromagnetic model for cold metal transfer wire arc additive manufacturing (CMT-WAAM)[J]. Additive Manufacturing, 2020, 36: 101541.

34. Gerhard P, Ferdinand K, Heinz H, et al. Manufacturing of turbine blades by shape giving CMT-Welding[C]//Proceedings of the Metal Additive Manufacturing Conference, 2014.

35. Somoskői G, Török I. CMT PIN–Define the shape of the welded PIN through welding parameters[J]. Production Processes and Systems, 2013, 6(1): 47-56.

36. Stelzer S, Ucsnik S, Pinter G. Fatigue behaviour of composite–composite joints reinforced with cold metal transfer welded pins[J]. International Journal of Fatigue, 2015, 81: 37-47.

37. Chen S, Li S, Li Y,et al. Butt welding-brazing of steel to Aluminum by hybrid laser-CMT[J]. Journal of Materials Processing Technology,2019, 272: 163-169.

38. Zhu Z Y, Liu Y L, Gou G Q, et al.Effect of heat input on interfacial characterization of the butter joint of hot-rolling CP-Ti/Q235 bimetallic sheets by Laser+CMT[J]. Scientific Reports,2021,11(1):10020.

编辑部网址:http://www.71dhj.com

ZHAO Kai 1 YANG Chenggang 2YI Xiang 3

(1. Jiangxi Hengda High Technology Co., Ltd., Nanchang 330096, China; 2. Nanchang Hangkong University, Nanchang 330063, China; 3. Zhuhai Fronius Welding Co., Ltd., Zhuhai 519051, China )

作者简介:赵 锴(1976—),男,博士,研究员,主要从事金属材料、焊接、激光熔覆等研发工作。E-mail:31609663@qq.com。

中图分类号: TG444

文章编号:1001-2303(2022)05-0060-07

文献标识码: A

本文编辑:唐凰

本文由焊割在线整理发布,转载请注明。